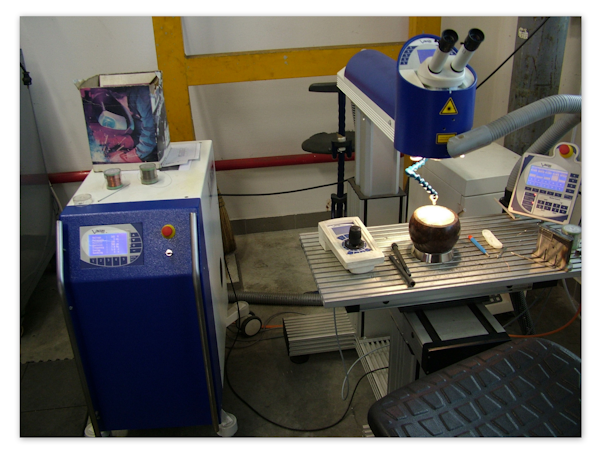

Making the finest join is possible only by the laser welding. You can apply it for different kinds of metals for example: compound steel and steel, nickel based steel cast, aliminium and its alloy, copper and its alloy and other precious metals for welding. The components of the tools that were made during quite long time and many other parts of the machines when they fail the repairing cost is much less by laser welding than buying a brand new one.

Application range:

- Worn, broken tools and cups and inlays their missing materials replacement by topping up laser welding.

- For repairing of warm duct, nozzles, peaks

- For material replacement and precise work of components, samples, pototypes

- For covering of etchworks (signs and numbers of materials and types) after grinding it can be re-etchwork (e.g. moulding injection tool)

- For repairing of polished surfaces

- For difficult to get at spot laser welding can be done, precise, exact and it can be assured in micron range too